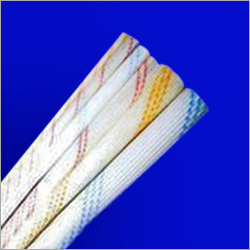

Motor Winding Fiberglass Sleeves

Motor Winding Fiberglass Sleeves Specification

- GSM

- 60150 gsm (depending on size and coating)

- Thickness

- 0.5 mm to 2.0 mm (customizable)

- Usage & Applications

- Electrical insulation for winding wires in motors, transformers, electrical equipment

- Shape

- Tubular Sleeve

- Temperature

- Continuous up to 155C, short term up to 200C

- Density

- 2.54 Gram per cubic centimeter(g/cm3)

- Thermal Conductivity

- Low, excellent thermal insulation properties

- Material

- Fiberglass

- Application

- Motor Winding Insulation

- Technique

- Braided

- Surface Treatment

- Heat Treated

- Dimension (L*W*H)

- Customizable (Typically supplied in rolls or cut to size as per requirement)

- Elongation

- Good mechanical strength, resistant to stretching and tearing

- Chemical Resistance

- Excellent resistance to oils, solvents, and most chemicals

- Breakdown Voltage

- 4 kV 7 kV depending on wall thickness

- Flame Retardant

- Yes

- Moisture Absorption

- Very low

- Flexibility

- Highly flexible and easy to apply

- Packaging Type

- Rolls, coils, or cut lengths

- Shelf Life

- Long, if stored in dry conditions

Motor Winding Fiberglass Sleeves Trade Information

- Minimum Order Quantity

- 200 Meters

- Supply Ability

- 500 Meters Per Day

- Delivery Time

- 7 Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- customized packing

- Main Domestic Market

- All India

About Motor Winding Fiberglass Sleeves

To meet the diversified requirements of the industry, we are catering our esteemed customers with an impressive range of Motor Winding Fibreglass Sleeves. To offer high quality of sleeves, we always use finest quality of fiberglass procured from most trustworthy vendors of the market. This range of sleeves is widely demanded for wiring insulation in the industry. Having strong mechanical and electrical strength, our array of Motor Winding Fibreglass Sleeves is acknowledged for its cost effective prices. We offer our stock of sleeves in accordance with the quality parameters as per the demands of the market.

Superior Electrical Insulation

Designed for motor winding and electrical insulation, our fiberglass sleeves ensure high dielectric strength and exceptional thermal insulation. Their insulating properties prevent electrical faults and enable your equipment to function safely and reliably in demanding environments.

Engineered for Demanding Environments

With a flame-retardant, oil-resistant, and solvent-resistant surface, these sleeves excel even in chemically aggressive or high-temperature settings. Their mechanical robustness ensures long-term reliability, resisting both stretching and tearing during use.

Customizable & Easy Application

Available in a range of thicknesses (0.5 mm to 2.0 mm), GSM options (60150 gsm), and supplied as rolls, coils, or cut-to-length, our sleeves can be tailored precisely to your project requirements. The braided construction ensures flexibility and makes handling and installation straightforward.

FAQs of Motor Winding Fiberglass Sleeves:

Q: How are Motor Winding Fiberglass Sleeves applied to electrical equipment?

A: The sleeves are slid over the winding wires of motors, transformers, or other electrical components, providing a protective and insulating layer. Their high flexibility and tubular braided construction make the application process quick and efficient.Q: What are the key benefits of using fiberglass sleeves for motor windings?

A: Fiberglass sleeves offer outstanding electrical insulation (4 kV 7 kV), excellent flame retardancy, and mechanical strength. They are resistant to oils, solvents, and moisture, making them ideal for protecting winding wires in high-stress environments.Q: When should I choose a specific thickness or GSM for my application?

A: Choose the thickness (0.5 mm2.0 mm) and GSM (60150) based on the required voltage protection, mechanical durability, and available installation space. Thicker sleeves are suitable for higher voltage or more robust protection needs.Q: Where can these fiberglass sleeves be used beyond motor windings?

A: These sleeves are versatile and suitable for insulating wiring in transformers, electrical panels, generators, and other electrical devices that require high dielectric and mechanical protection.Q: What process is used to manufacture these fiberglass sleeves?

A: The sleeves are manufactured using a braided technique with heat-treated fiberglass material. This process enhances their flexibility, ensures consistent wall thickness, and improves their performance under mechanical and thermal stress.Q: How do these sleeves perform in terms of chemical and moisture resistance?

A: The sleeves provide excellent resistance to oils, solvents, and most chemicals, and have very low moisture absorption. This maintains insulation integrity and prevents degradation over time, even in harsh environmental conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Fiberglass Sleeves Category

Fiberglass Sleevings

Price 2 INR / Meter

Minimum Order Quantity : 1000 Meters

Shape : Tubular

Thermal Conductivity : 0.035 W/mK

Application : Electrical insulation, wiring harness protection, cable sleeve

Surface Treatment : Heat cleaned

Fiberglass Sleeving

Price 1 INR / Meter

Minimum Order Quantity : 200 Meters

Shape : Round

Thermal Conductivity : 0.035 W/mK

Application : Electrical insulation, thermal insulation, protection of wires and cables

Surface Treatment : Silicone coated

Varnish Fibreglass Sleeve

Price 2 INR / Meter

Minimum Order Quantity : 1000 Meters

Shape : Tubular sleeve

Thermal Conductivity : Low, designed for insulation purposes

Application : Electrical insulation, transformer and motor winding protection

Surface Treatment : Varnish coated

PVC Fiber Glass Sleeves

Price 1 INR / Meter

Minimum Order Quantity : 1000 Meters

Shape : Sleeve / Tubular

Thermal Conductivity : Low, suitable for high electrical insulation

Application : Wire harness, electrical insulation, thermal protection in automotive, home appliances, and electronic devices

Surface Treatment : PVC Coated

|

VAISHNO ENTERPRISES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |